- Vision

- To be a strong EPC contractor in the fields of energy production and oil and gas projects.

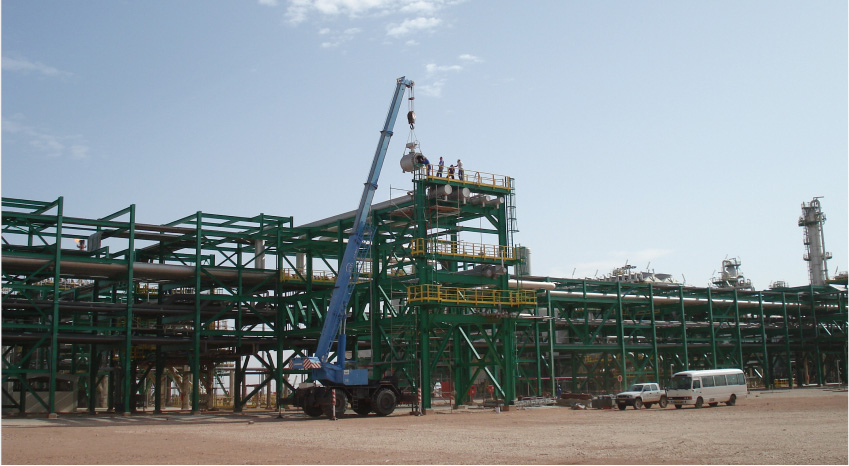

FIAL’s construction activities cover all disciplines using own construction and maintenance Equipment.

The Integrated Management System in Ferrostaal Industrieanlagen Libyen Ltd. is based on following certifications:

The FIAL Health, Safety, Security and Environmental (HSSE) policy enunciates the philosophy and commitment of FIAL, supported by the HSSE Department, towards environmental protection and managements of Health, Safety and Security of FIAL employees, subcontractors and clients, covering the project management, design, engineering, construction, commissioning, offices and camps activities. All FIAL Team are committed to demonstrating high standard for environmental protection, sharing of best practices and provision of safe, secure, and healthy workplaces based on our values of Competence, Experience, Teamwork, Performance, and Flexibility.

To be one of the strongest EPC contractors in the oil & gas and energy production fields projects in Libya, with a quality and service culture that enables us to exceed customer expectations and to be a reference with QHSE requirements.

Provide our clients with the best EPC projects, with high Quality level in good Health, Safety conditions, and Environmental protection, with the highest sustainability level in timely execution and cost-efficient manner. Achieving all requirements to satisfy all interested parties.

Ferrostaal has adopted a strong Culture supported by QHSE Management System for Quality, Health, Safety and Environment, promoting quality in its services, and protecting the health, safety and welfare of its employees, personnel acting on our behalf, and protecting our surrounding environment.

Ferrostaal at all worksites is committed to:

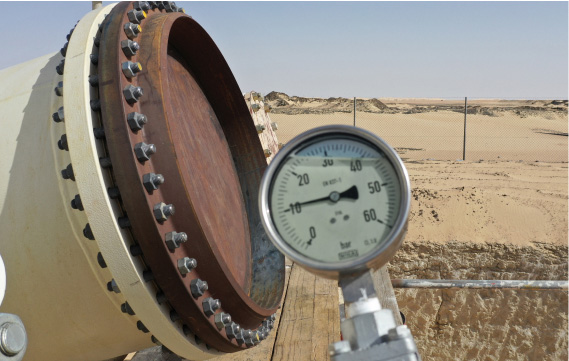

In 2016, as a result of the improvement of the political situation in Libya, AGOCO (Arabian Gulf Oil Company) relaunched the flares gas recovery project in several SARIR Sites (located in the eastern part of the country, about 600km south of Benghazi) with a view to use the gas as fuel for the power plant of its GRAMA water pumping unit (located about 300km West of SARIR) to the Mediterranean coast. The key events and / or dates of this ongoing project are:

Formerly LASMO Grand Maghreb Limited F-NC-174 (Elephant) Development Project - EPC for GOSP

This project consisted of the engineering, procurement, installation/construction, pre-commissioning and commissioning of the following:

Installation of Skid Mounted Water Disposal Units /OMV

The project is in Nafoora oil field – Libya, more specifically in GOSPs 4, 5 and 6.

NAFOORA 91 JOINT PROJECT TEAM, herein referred to as the COMPANY, has contracted the complete installation of four water disposal units, each one consisting in three API separators and the associated utilities and pumping station, in GOSP 4, GOSP 5 and GOSP 6 of Nafoora oil field in Libya.

The Wafa field is about 525 KM in Southern West part of Libya adjacent to the Libyan-Algerian boarder.

Company Intended to increase Wafa Desert Plant Sales Gas production from its design capacity of 531,000 SM3/h to 584,000 SM3/h (Defined as Stage-1)

In order to achieve this objective, the scope of work outlines the requirements upon which the CONTRACTOR shall carry out the WORKS and other SERVICES for the replacement of some pressure Relief valves; the works/services include but are not limited to site survey, engineering, procurement and supply of all materials related to piping and mechanical, construction and installation.

Execution of the following field facilities at the El-Sharara Development Project’s NC-115, NC-186 and IR fields:

The project included all associated electrical, instrumentation, building and civil works.

Formerly Wintershall Libya (WILI) GOSP Jakhira, Concession 96 – Gas Lift Repair (GLR) Project

FIAL offers rewarding careers for high-performing individuals. We are committed to an inclusive environment where people feel comfortable to themselves. We want our people to feel that all voices are heard, and all cultures, religions and backgrounds are respected. We’re constantly searching for passionate people to join our talented team.

If you would like to be considered for a position with us, kindly submit an application and include your CV: fial.hr@fial-oil-gas.com

Some of our major clients are listed below: